Biomechanics - Mechanics of biological tissues

Research

Biomechanics and Mechanics of Biological Tissues aims to study the mechanical functionality of biological tissues and structures, considering both healthy and pathological conditions and taking into account interaction phenomena with biomedical, surgical and prosthetic devices.

Investigations are often developed through experiments on animal models and clinical trials. On the other hand, the use of computational methods can reduce and replace such activities, drastically reducing ethical, time and economic costs. The development of computational models requires coupled experimental and computational activities. CT and MRI data provide information for the geometrical characterisation of the anatomical region. Histological analysis and mechanical tests on biological samples from human and animal models allow the constitutive definition and identification of tissue mechanics.

Subsequently, the computational approach allows in silico analysis of procedures and device functionality, taking into account the influence of many variables that would be costly and time-consuming to study experimentally. Furthermore, computational methods provide data that are difficult to obtain from experimental activities, such as the strain and stress fields that regulate important mechano-biological phenomena.

In this sense, the methods of biomechanics and mechanics of biological tissues provide a powerful, reliable and sustainable methodology for the investigation of biomedical procedures and devices. In conclusion, a unique approach is adopted where in silico mathematical modelling, in vitro testing and in vivo testing are synergistically integrated to rationally design novel procedures and devices.

search activities are carried out within the CMBM and in collaboration with international research centres. Extended relationships are maintained with European and North American universities, research centres and industry to develop international research projects.

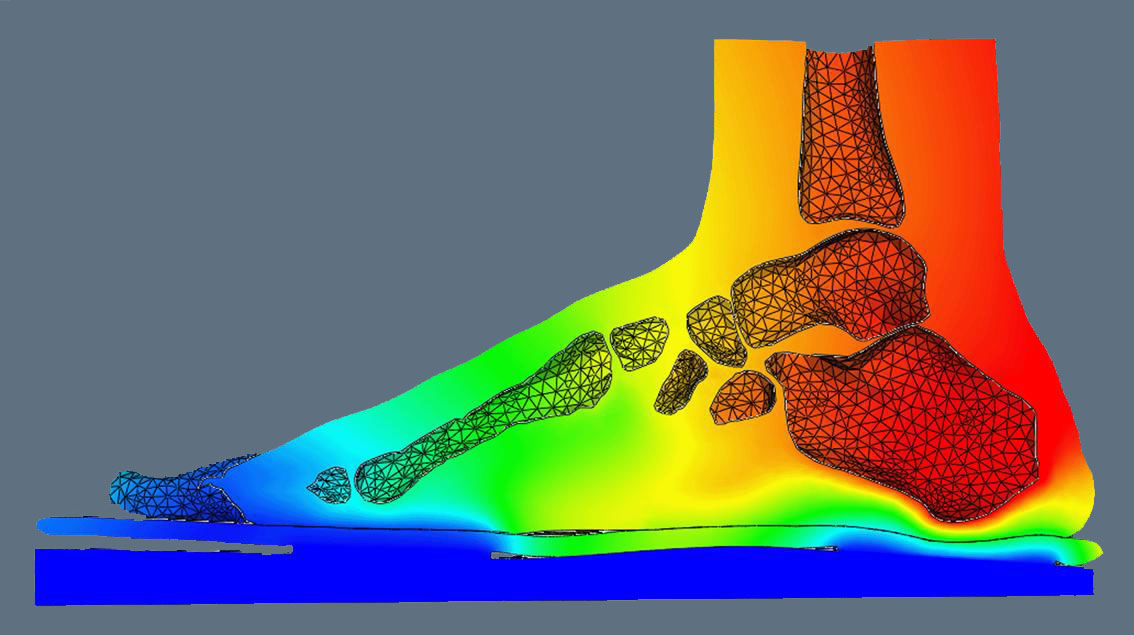

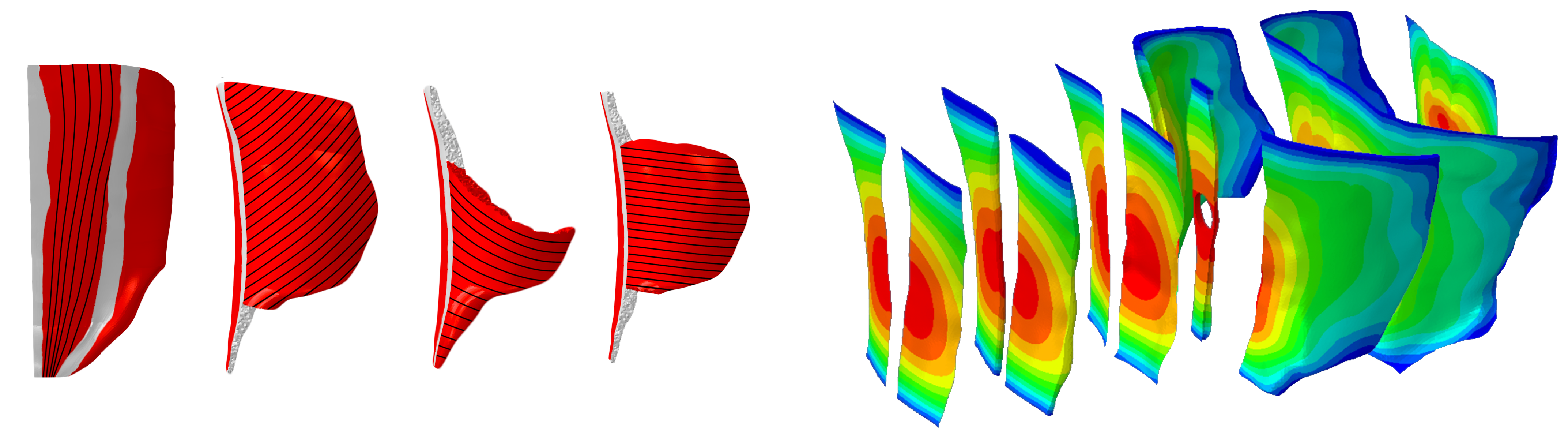

Examples of foot modeling

Educational Program

At the University of Padua, the teaching activity is carried out through the courses of Biomechanics, Tissue Mechanics and Computational Biomechanics, which belong to the Faculty of Engineering, within the framework of the Biomedical Engineering and Bioengineering degrees.

The Faculty of Medicine offers courses in Biomechanics and in Mechanics of Biological Tissues. Advanced courses in biomedical and materials engineering for postgraduates, doctoral students and professionals are offered with the support of the European Commission, involving universities, research centres and industry.

Equipment

Software and hardware for computational modelling are the main equipment at disposal. In particular, general purpose finite elements software, pre- and post-processors are used, even if relevance is given to homemade codes developed for specific advanced problems. The hardware equipment is composed by High Performance Computing workstations and servers:

HPC Server Fujitsu Primergy RX4770 M3 (96 cores – 192 threads Intel Xeon E7 8890 v4, 512 GB RAM, SSD HD)

HPC Server LENOVO ThinkSystem SR950 (192 cores – 384 threads Intel Xeon Platinum 8260, 2 TB RAM, SSD HD)

Mechanical and coupled linear and non-linear analyses are carried out by using the general-purpose software Abaqus Standard and Abaqus Explicit, FEBio and Comsol Multiphysics. Pre- and Post-processing of computational models is performed by means of Materialise NV Mimics, 3D Systems Geomagic and Abaqus CAE.

Experimental activity is carried out by using specific equipment for testing biological tissues and biomaterials:

Bose ElectroForce Planar Biaxial Test System

Uni- and Bi-axial mechanical testing

Different load cells with capacity up to 22 N, 200 N, 400 N

Optical system for strain evaluation

Bio-reactor to test tissues and biomaterials maintaining them in a controlled or sterile environment

Biomomentum model Mach-1 v500csst MA009

Multiaxial mechanical testing of tissues and biomaterials (tensile and compression loading, shear, torsion and indentation)

Different load cells with capacity up to 1.5 N (uniaxial), 17 N (multiaxial), 70 N (multiaxial) and 250 N (uniaxial)

Optical system for strain evaluation

Mechanics of biological structures

The characterization of the mechanical behavior of biological structures is developed by means of inflation tests, using an ad hoc developed testbench, which is equipped with a Verderflex Peristaltic Pump, pressure and flow sensors, and National Instruments acquisition devices.

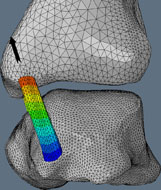

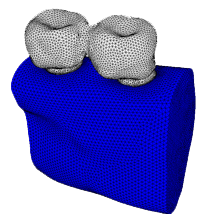

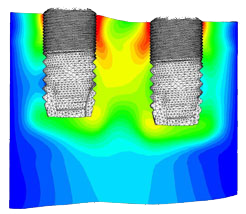

Example of numerical modelling in dental mechanics

Interaction phenomena occurring between dental implants and cortical-trabecular tissues in the lower jaw reported with regard to the misfit condition induced by the coupling of the bar with the implants.

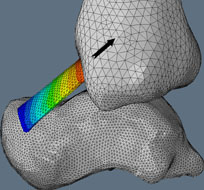

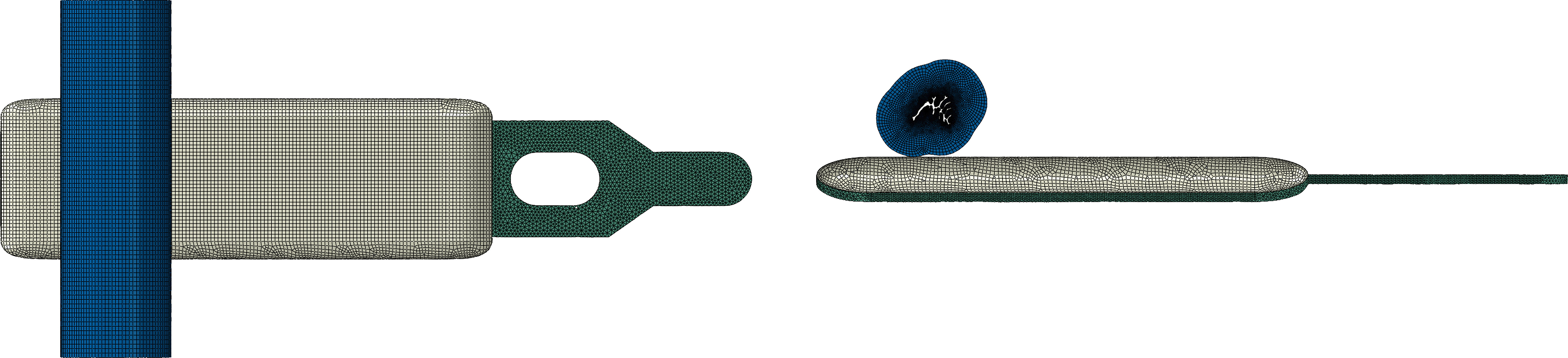

Example of numerical modelling in uretra mechanics

Interaction phenomena occurring between dental implants and cortical-trabecular tissues in the lower jaw reported with regard to the misfit condition induced by the coupling of the bar with the implants.

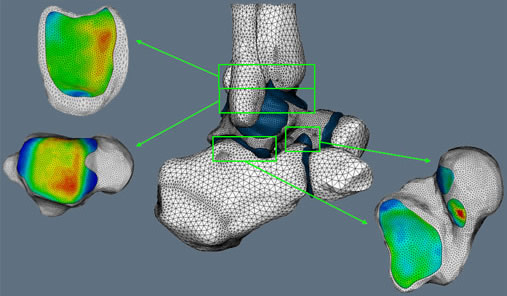

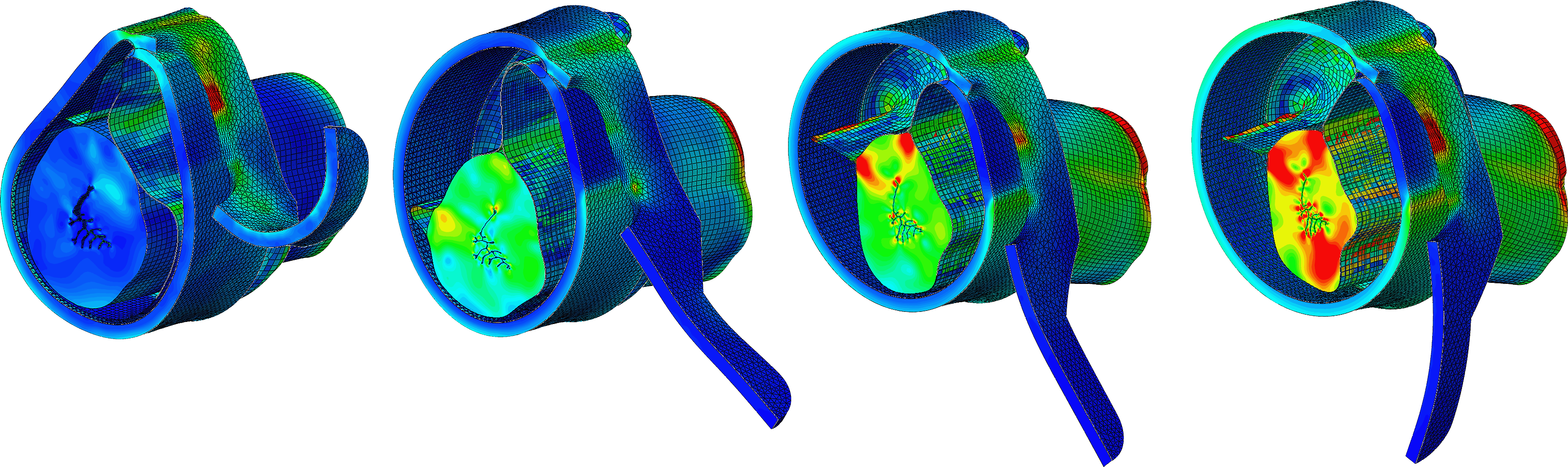

Example of numerical modelling in abdominal wall mechanics

The use of a synthetic meshes for abdominal hernia repair is investigated by numerical model that interprets the different phases of the surgical procedure. The effects induced by active contraction of the abdominal muscular system are also considered.