Polymers

Research

The team, headed by Prof. Michele Modesti, is active since about 25 years in the field of polymeric materials synthesis, charcterization and processing at academic and applied (industrial) level. People working in the group are highly qualified in polymer engineering science, with different academic degrees: full time researchers, post-doc, PhD and graduated students, technicians.

International academic partnerships:

Queens University of Belfast – Dept. of Mechanical and Aerospace Engineering (UK), Polytechnic of Krackow (PL), University of Warsaw (PL), Duisburg-Essen University (D), National University of Singapore (Singapore), Universidad Nacional de Salta (Argentina), National Institute of Standards and Technology (USA), Penn-State University (USA), University of California (USA).

In detail research topics are:

- polymer composites and nanocomposites

- chemical and physical recycling of polymers

- fire behavior of polymers

- polymer processing and formulation

- nanostructured polymeric membranes

The research activity about this last topic mainly focuses on the design and development of multifunctional nanofribous scaffolds which have a huge potential within nanotechnology field, especially in tissue engineering. These membranes are obtained by electro-hydrodynamic technologies (ehd), (electrospinning and electrospraying) and they can be tailored according to the specific application.

In particular lab’s research deals with:

- Electrospun scaffolds based on hyaluronan materials for wound healing;

- Design and development of advanced filter media for blood filtration based on electrospun biopolymers (starch based polymers);

- Electrospun scaffolds of self-assembling peptides with poly(ethylene oxide) for bone tissue engineering;

- Electrospun membranes with antimicrobial activity;

- Electrospun multi-structured membrane for degradation of volatile organic compounds (vocs);

Almost all the projects are carried out thanks to the partnership with private companies and academic networks with different academic groups. In 2008 a spin-off company of polymer engineering lab, that is Nanowebfun s.r.l., was founded with the mission of the developement of ehd processes for the production of nanostructured membranes.

Educational Program

Industrial chemical processes 2 (master degree chemical engineering)

Plastics engineered product design (master degree product engineering)

Polymer engineering and recycling (master degree chemical engineering)

Innovative chemical processes (master degree chemical engineering)

Equipment

The following equipments are currently available:

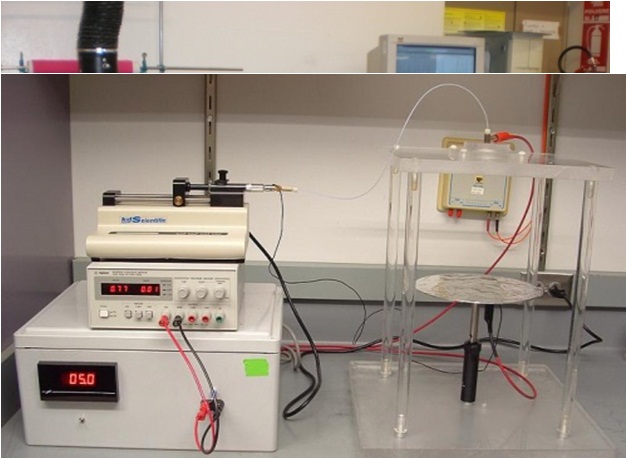

- polymer processing – single and twin screw lab scale extruders, injection and compression molding machines, brabender® plastograph, solution and melt electrospinning stations;

- chemical characterization – FT-IR spectroscopy, GC-MS and HPLC cromatography, TGA/FTIR and TGA/GEMS;

- physical characterization – mechanical properties (tensile, flexural, impact), gas permeability, electric properties, water content titrators;

- thermal characterization – thermal—gravimetric anaysis (TGA), differential calorimetric analysis (DSC), dynamic mechanical analysis (DMA), thermal conductivity of foams;

- fire behavior – small scale flamability tests, limiting oxygen index (loi);

- microscopy – optical and environmental scanning electron micriscopy (e-sem);

- process simulation – moldflow plastics insight for injection molding simulation;